The concept of the heat pipe was first proposed by R.S. Gaugler of Ohio General Engine Company in the patent "NO.2350348" in 1944, but it was not implemented at that time until the term "Heat Pipe" was first mentioned in a paper published by G.M. Grover in 1963.

The initial development of the heat pipe was applied to space technology. In response to the environment of no gravity field in space, the return of the working fluid to the heating part cannot rely on the action of gravity, so the liquid must be sent back by capillary action. The overall mass is very light. This is the heat pipe. The first feature is also one of the reasons for the application of space technology. The initial research is also centered on spaceships. In 1966, RCA Corporation of the United States first commercialized heat pipes. Since then, heat pipes have been widely used on the ground.

Including artificial satellites, waste heat recovery from boilers, motor cooling, solar energy, and geothermal heat, all of which effectively use the principle of heat conduction. Among them, the application of cooling electrical appliances and electronic parts is more directly penetrated into the lives of each of us.

Principle And How

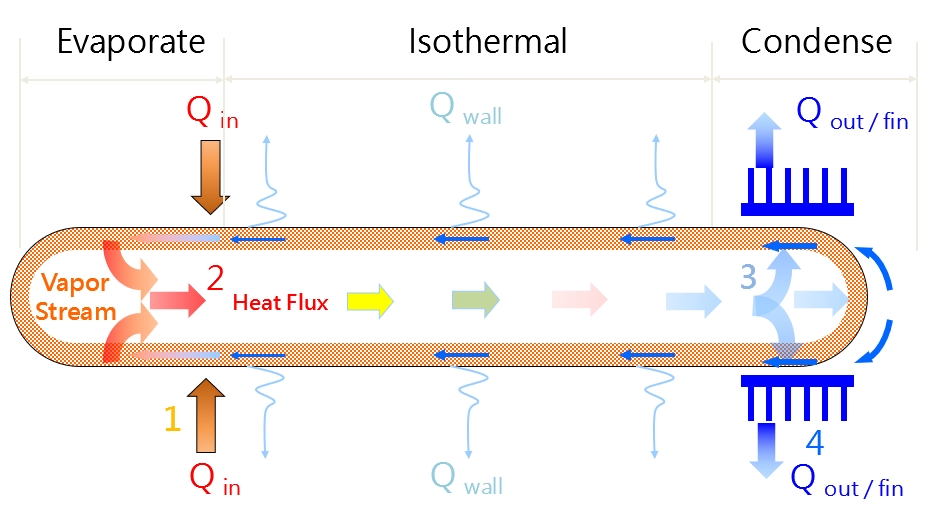

When the heat pipe is in operation, the working fluid in the evaporating section absorbs heat through the tube wall and vaporizes to generate high-pressure steam. The high vapor pressure will drive the generated steam to rush to the condensing section through the adiabatic section, and release latent heat due to condensation and condense into a saturated liquid. The working liquid generated by condensation will flow back to the evaporation section through the capillary pressure generated by the capillary structure and surface tension. When the capillary pressure is sufficient, the working liquid can be continuously sent back to the evaporation section. In this way, the evaporation-condensation process can be repeated and become a cycle.

Usually, after liquid is injected into the tube, vacuuming is performed. The main purpose is to reduce the saturated vapor pressure in the tube, so that the working fluid can evaporate at a relatively low temperature, driving the thermal cycle, and repeating to achieve the effect of heat transfer.